Something big is happening in Utah, in Asphalt Ridge, where geologists believe there is potentially 1 billion barrels of oil recoverable from oil sands, and where a new breakthrough technology has proven cost-effective at producing ‘clean’ oil sands in a win-win situation for both investors and environmentalists.

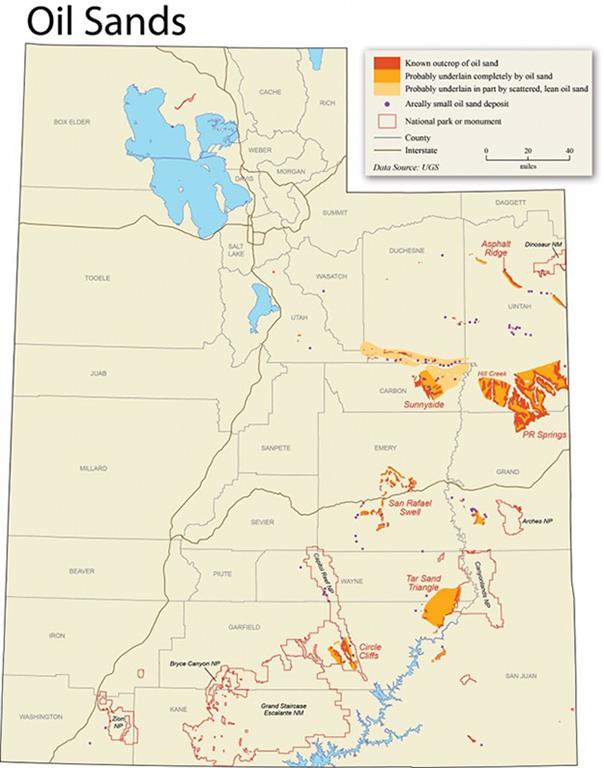

Asphalt Ridge is part of the prolific Green River Formation, which spans Utah, Wyoming and Colorado and may hold some 3 trillion barrels of recoverable oil. Utah is the heart of this waking beast, with estimated in-place tar sands oil resources of 32 billion barrels. And at the heart of the heart is Asphalt Ridge, which is thought to contain nearly a billion barrels of oil on its own.

But Utah is more than just a part of the resource-rich Green River Formation—it’s also the proving ground for the latest technology that ensures we get the most out of our oil sands without leaving behind the toxic trailing ponds that have plagued Alberta’s industry.

The new technology—patented by MCW Energy Group (traded in the US under MCWEF and in Canada under MCW.V)—relies on a solvent that uses no water and produces no waste or pollutants, and produces at $27-$30 per barrel.

Toronto-based MCW Energy has been operating its Asphalt Ridge oil sands project since October 2014, and for the past five years it has been working closely with Utah's Responsible Energy Development program to meet—and in some cases exceed—environmental requirements.

Beginning in January 2015, the Asphalt Ridge project has been producing 250 barrels per day of clean oil sands, against the backdrop of intensifying protests by environmentalists who are decrying other oil sands projects in the state for dangerous pollutants.

The Asphalt Ridge technology may be exactly what Utah needs to produce oil from oil sands without tapping into the state’s already sparse water supplies, without turning out dirty oil for potentially catastrophic pipeline leaks, and without returning contaminated sand to the ground. The process is also not reliant on high temperatures or pressures—and it doesn’t emit any greenhouse gases, according to MCW CEO Dr. R. Gerald Bailey, former ExxonMobil (NYSE:XOM) president of Arabian Gulf operations.

A key difference between Utah and Alberta is the nature of the oil sands itself. Utah’s oil sands are oil-wet as opposed to water-wet, which means they can simply be scooped up and processed with the new solvent. The oil is separated and the sand is returned to the ground 99 percent cleaned.

Not only is this clean oil sands project coming out at $27-$30 per barrel in prices that rival OPEC’s average, but once financing goes through for a second 5,000-barrel-per-day plant at the nearby Temple Mountain, the cost per barrel is expected to be reduced to $20.

On 8 September 2015, MCW closed the acquisition of TMC Capital, LLC, giving it the Temple Mountain Project oil sands lease. This project will supply more oil sands for Asphalt Ridge and also serve as the location for the company’s planned 5,000-bpd extraction plant to further drive down costs.

In the meantime, while shale producers are taking a nose-dive in the market, experts estimate that production using this new technology in Utah is more profitable than shale oil currently being produced, and more profitable than any other oil sands project in North America.

It costs about $55 per barrel to produce oil sands in Alberta, compared to Asphalt Ridge’s approximately $30 for clean oil sands. We could even be looking at a shift in focus to clean oil sands and away from Utah’s more expensive-to-produce shale, which had earlier attracted major players such as Marathon Oil (NYSE:MRO), EP Energy Corporation (NYSE:EPE) and Newfield Exploration Co. (NYSE:NFX).

An independent Chapman Engineering Report concludes that MCW’s extraction technology is an innovation with no rivals, particularly from an energy-efficiency perspective.

For investors, today’s emerging playing field is all about de-risking production in terms of regulatory delays and environmental hiccups while at the same time coming in at a cost that can survive the oil price slump. At the end of the day, the Asphalt Ridge project seems to tick both of these boxes as depressed oil prices and environmental activism push new technological innovations harder and faster.

Legal Disclaimer/Disclosure: This document is not and should not be construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment. No information in this Report should be construed as individualized investment advice. A licensed financial advisor should be consulted prior to making any investment decision. We make no guarantee, representation or warranty and accept no responsibility or liability as to its accuracy or completeness. We assumes no warranty, liability or guarantee for the current relevance, correctness or completeness of any information provided within this Report and will not be held liable for the consequence of reliance upon any opinion or statement contained herein or any omission. Furthermore, we assume no liability for any direct or indirect loss or damage or, in particular, for lost profit, which you may incur as a result of the use and existence of the information, provided within this Report.